Teflon Mold Release Tape, used for Aircraft composites manufacturing

Teflon Mold Release Tape, make of woven fiberglass fabric coated with high quality PTFE(TEFLON), and coated with Silicone PSA on the back side. This mold release tape has higher tensile strength than normal self adhesive PTFE fabric. In this case, ESONE adhesive tape will be easily took down after repeatedly used.

ESONE mold release adhesive fabric is used to stick the molding, for the manufacturing of aircraft composites, wind power blade composite, like satcom and weather radomes, helicopter rotor blade, structural components like wings, tail section, fuselage component and so on.

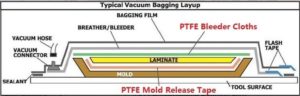

How to use Vacuum bagging bleeder cloths and Teflon Mold release tape

Click here to access the Vacuum Bagging Bleeder Cloths

Vacuum bagging system is consist of vacuum bag, ventilated felt, cover, isolating membrane, bleeder, bleeder cloth(Porous PTFE fabric), composite, Teflon Mold Release Tape(PTFE adhesive fabric) and molding.

After extracting vacuum, autoclave molding will release high temperature, high pressure by adding heat compression air, for the curing and molding of the composite. And ESONE PTFE coated fabric will provide a easy and clean release after curing process, air, resin and volatile will be allowed for escaping.

The surface of composite will be excellent smooth by using Teflon Mold Release Tape and Vacuum bagging bleeder cloths, and composite will be very easy to peeled off from the PTFE peel ply after cured.

Property of PTFE Release Film

★ Easy release and non stick.

Composite will be easy and clean released from bleeder cloths.

★ Create super smooth surface for composite

After release, the composite will have a excellent smooth and shiny surface, such as resin reinforced carbon fiber bonnet of automotive.

★ Strong mechanical strength

Teflon Mold Release Tape has high tensile strength, which can resist the several cycles of high pressure in vacuum bagging and is reusable, due to adhesive tape will not be tore when releasing from molding.

In these applications, the release property, mechanical strength and porosity of Teflon Mold Release Tape is critical to the manufacturing process and the quality of the composites.

Applications of PTFE molding release tape

1) Helicopter blade

ESONE is selling PTFE mold release film and bleeder cloth to Helicopter blade industry, which has high request of the mechanical strength, in order for reuse mold release tape many times.

2) Airplane composite manufacturing

ESONE PTFE coated fabric is used in composite mold protection and release liners, vacuum bagging bleeder cloths, which result in a excellent smooth and shiny surface of the airplane composite, like fuselage components, wings, tail and so on.

3) satcom and weather radomes

Satcom and weather radomes are made of resin reinforced fiberglass composite, which will use vacuum bagging system for composition.

4) Wind power blade composite

Molding for wind power blade is very large and long, if PTFE mold release fabric or bleeder cloth got any problem, then all the molding will be influenced. In this case, this industry has high request of the quality of PTFE coated fabric.

Specification of PTFE Bleeder Cloth

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC | POROUS SERIES | PTFE(TEFLON) |

| Properties | Metric | Imperial |

|---|---|---|

| Standard width Please ask for other widths | 1000 mm | 39.5 inches |

| Thickness | 0.06 mm | 0.0024 inches |

| Coated weight | 66 g/m² | 1.95 oz/yd² |

| PTFE content | 27 % | 27 % |

| Porosity | 20-100 cfm | 20-100 cfm |

| Tensile strength | 160 N/cm Warp | 91.5 lbs/inches Warp |

| 146 N/cm Fill | 83.5 lbs/inches Warp | |

| Temperature resistance | -73 to +260 °C | -100 to +500 °F |

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC SELF ADHESIVE | TEAR RESISTANT SERIES | SILICONE PSA |

| Properties | Metric | Imperial |

|---|---|---|

| Standard width Please ask for other widths | 1000, 1250 mm | 39.5, 49.3 inches |

| Backing Thickness PTFE glass | 0.07 mm | 0.0028 inches |

| Total Thickness PTFE glass and Silicone PSA | 0.115 mm | 0.0071 inches |

| Baking weight PTFE glass | 130 g/m² | 3.85 oz/yd² |

| Tensile Strength PTFE glass | 150 N/cm Warp | 85.7 lbs/inches Warp |

| 141 N/cm Fill | 80.5 lbs/inches Fill | |

| Adhesion | 4 N/cm | 36.3 oz/inches |

| Temperature resistance | -73 to +260 °C | -100 to +500 °F |

Technical data sheet of PTFE Mold Release Tape, YS7007AT-ESONE, YS7013AT-ESONE

Pingback: PTFE Tear Resistant Fabrics, increased tear and crease strength property. | PTFE & Silicone Coated Fiberglass Fabric, Tape, Belts

Pingback: Meet ESONE New Material in China Composites Expo 2017 | PTFE & Silicone Coated Fiberglass Fabric, Tape, Belts